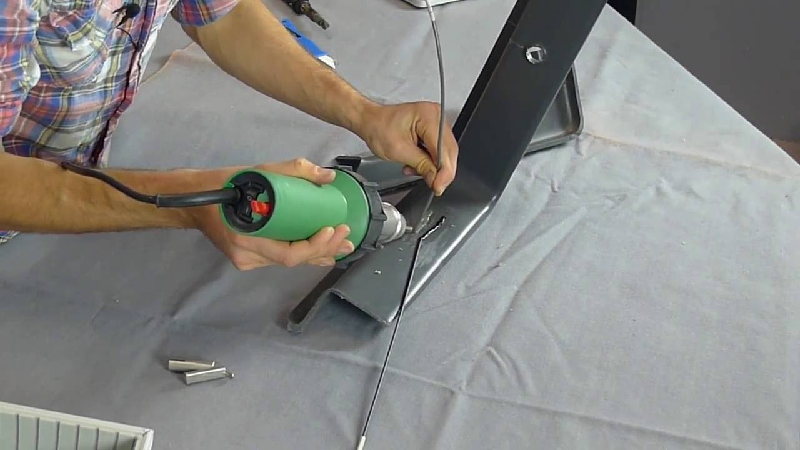

The ubiquity of plastic often leads to people assuming that, when a plastic part cracks or breaks, they should just replace it. However, sometimes the part can be fixed at a fraction of the cost, instead. Plastic welding repairs make it possible to restore the integrity and function of bumpers, water or chemical tanks, pipes, cleanroom or medical equipment and more. The process also sees use in manufacturing, when a product must be fabricated in separate parts that are then joined.

How Plastic Welding Works

Most people are more familiar with metal welding than plastic welding, but many of the underlying principles work for plastics as they do with metals. Broadly, welding joins two surfaces together with heat and pressure, bonding them seamlessly. Many methods of plastic welding exist, but the general process is always the same:

- Pressure is applied to the parts to be welded, creating an interface between them and holding them in the proper position during welding.

- The interface is heated, allowing molecules to diffuse between the surfaces in contact.

- While still holding the parts under pressure, the welded area is allowed to cool, solidifying the bond.

Because the plastic bonds at the molecular level, the result is, for all intents and purposes, a single solid piece.

What Plastics Can Be Welded?

Not all plastics respond to heating and cooling the same way. Most plastics can be categorized as either thermoplastics (or thermosoftening plastics) or thermosets (or thermosetting plastics). Thermoplastics are composed of long macromolecules that join together with intermolecular forces—heating weakens these forces and cooling allows the molecules to reassemble. This allows thermoplastics to be molded, reshaped, recycled and welded. In contrast, thermosets harden irreversibly because the polymers form cross-links that essentially unite them as a single molecular unit. While significantly stronger, this means that high heat will cause the polymers to break down instead of entering a molten state.

Because of the ease of production, thermoplastics have a variety of applications. Common thermoplastics include nylon, Teflon, polyvinyl chloride (PVC), polycarbonates, polyethylene and acrylics.

What Makes a Good Plastic Weld

While thermoplastics can be heated and cooled without loss of mechanical properties, this doesn’t mean that every weld is perfect. An improper weld can fail to bond the interface surfaces, causing them to come apart, or even damage the plastic itself. Some factors in the quality of plastic welding include:

- The parts must be properly fixed in place to allow molecular diffusion, as well as to prevent warping when the material contracts as it cools;

- The temperature must be high enough to melt the plastic, but not so high that it burns instead;

- Proper welding takes time, both for the heating and cooling phases, to ensure a bond;

- The parts must be compatible, typically meaning being made of the same plastic, and the surface must be free of moisture or impurity.